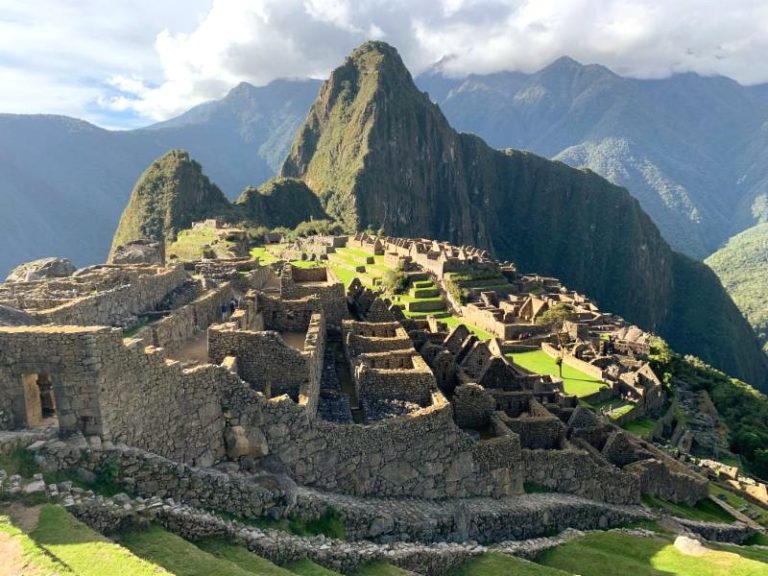

Machu Picchu Pueblo is the first city in Latin America to sustainably manage 100% of its solid waste.

Through the process of pyrolysis, in which the waste is decomposed at high temperatures without oxygen, 7 tons of trash is processed per day, generating bio-coal, a natural fertilizer that will be used to restore the Andean cloud forest and contribute to the agricultural productivity of Machu Picchu. Continuing initiatives for the conservation and environmental care of Machu Picchu, AJE Group and Inkaterra presented this first Organic Waste Treatment Plant to the city.

Alongside the Organic Waste Treatment Plant, a Plastic Compactor Plant to SERNANP will be used to recycle trash found along the Inca Trail, the most famous trekking route in South America. The plant was donated in 2017 and prevented the ruins of Machu Picchu from entering UNESCO’s list of Heritage at Risk. Currently, 14 tons of polyester plastic are processed daily in this plant.

In 2018, a Biodiesel and Glycerin Plant was inaugurated at Inkaterra Machu Picchu Pueblo Hotel. By processing used vegetable oil from Machu Picchu’s homes, lodges, hotels, and restaurants, 20 gallons of biodiesel are produced daily from nearly 6,000 liters of used oil a month. The glycerin obtained in the process of making biodiesel is also used by the municipality to clean the stone floors, thus replacing chemical products.

GOT NEWS? click here

Google News, Bing News, Yahoo News, 200+ publications

These cumulative efforts to turn the city of Machu Picchu into a model of global sustainability won the Peruvian “Líderes + 1” prize and, in Germany, the prestigious “Die Goldene Palme” award in the category for Responsible Tourism.

For more information on Inkaterra Machu Picchu Pueblo Hotel, click here.